Access Laser Company (ALC) has been providing high-performance longwave infrared and midwave infrared lasers since 1999, and always with an eye towards pushing the envelope of laser technology. Focused on application specific solutions, we’ve partnered with some of the worlds leading organizations in scientific research, semiconductor manufacturing and medical devices. Over our twenty plus year history we’ve delivered tens of thousands of products around the world, ranging from the humid factories in south east Asia to supporting the most sensitive measurements ever made at the Laser Interferometer Gravitational-Wave Observatory in the United States and Europe.

This dedication to providing the highest standards of reliability began in 2008, shortly after partnering with a leading medical device manufacturer, ALC quintupled its manufacturing headquarters. Understanding the importance of each unit having identical characteristics to meet appropriate safety standards we implemented strict sourcing and testing. In 2015, as ALC continued growing, our management team invested in meeting the highest standards for our customers in semiconductor photolithography. Building an ISO-7 cleanroom as an extension of our then campus which increased our capacity by 40%. This dramatic step alleviated the concerns of the world’s leading photolithography system provider and paved the way to our acquisition by TRUMPF.

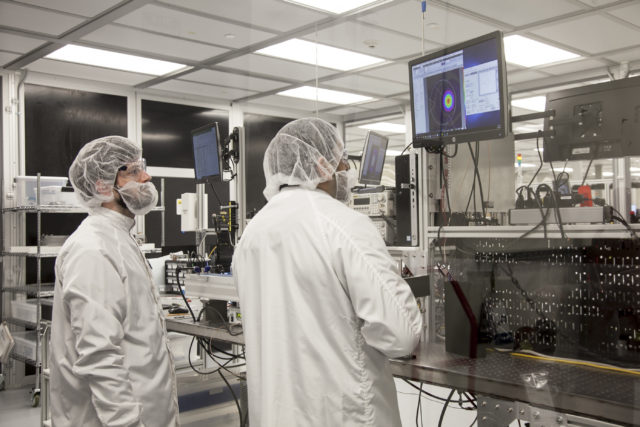

Figure 1: ALC final testing in our ISO-7 manufacturing cleanroom

In 2018, ALC moved its headquarters to our current manufacturing center, designed from the ground up to ensure an ISO-7 operations environment for our highest volume customers in semiconductor fabrication, medical surgery and leading-edge research. Tremendous improvements were made throughout the rest of our operations and supply chain, including a robust ISO-8 environment for final testing of all shipped orders. Parts arrive and are cleaned thoroughly using a variety of custom, proprietary processing steps before being inspected under ultraviolet light to remove even minute particulate. These cleanliness measures ensure our products are manufactured under repeatable conditions and contribute significantly to the long lifetime of each laser. Specialty processing equipment necessary for achieving our high standards of optical performance are in their own section of this cleanroom enclosure, allowing for parts to be seamlessly handled from assembly to final test. Not only do we pursue the highest level of excellence for our own materials and processes, but the vendors we partner with share these values. Over the past twenty years of operation Access Laser has built a strong, flexible supply chain which can meet the growing and varied demands presented by our world class customers in photolithography, medical device manufacturing and precision fiber optic fabrication. Because many of our customers are essential businesses in critical infrastructures, we understand the importance of providing products that can meet the rigor of 24/7 manufacturing, conducting extensive life testing on all of our product lines before qualifying them for integration to our leading OEM clients.

Due to the high level of custom orders we field from around the globe, our engineering labs are also kept to the ISO-8 standard. Truncating supply chain constraints we’ve added a multi-axis CNC machine that can provide the custom parts necessary for order-specific customization. To compliment the infrastructure investments made, we’ve also staffed an engineering team dedicated towards continuous improvement. This has led to the adoption and implementation of lean Six Sigma manufacturing processes that further support our ability to produce reliable products of world class quality.

Figure 2: ALC ISO-8 manufacturing cleanroom

Today Access Laser has thousands of lasers in the field built, tested and certified by highly trained technicians in our carefully monitored facility. Providing quality products that meet the unique performance requirements of our customers and provide an ease of mind that every product has been cared for to insure longevity and repeatability. This commitment to quality and continuous improvement is what pushes us to surpass the expectations of our customers.